BUILDING A HANA: FINAL TESTING, INSPECTION AND PACKAGING

4: FINAL TESTING, INSPECTION AND PACKAGING

The cartridge undergoes rigorous testing to ensure precision in tracking, channel balance, separation, and distortion-free performance. Using specialised tools, the technician evaluates each unit and makes fine suspension adjustments as needed. Once approved, the cartridge is carefully mounted into its model-specific body, tested for the highest quality control and finally boxed, completing the process with absolute precision.

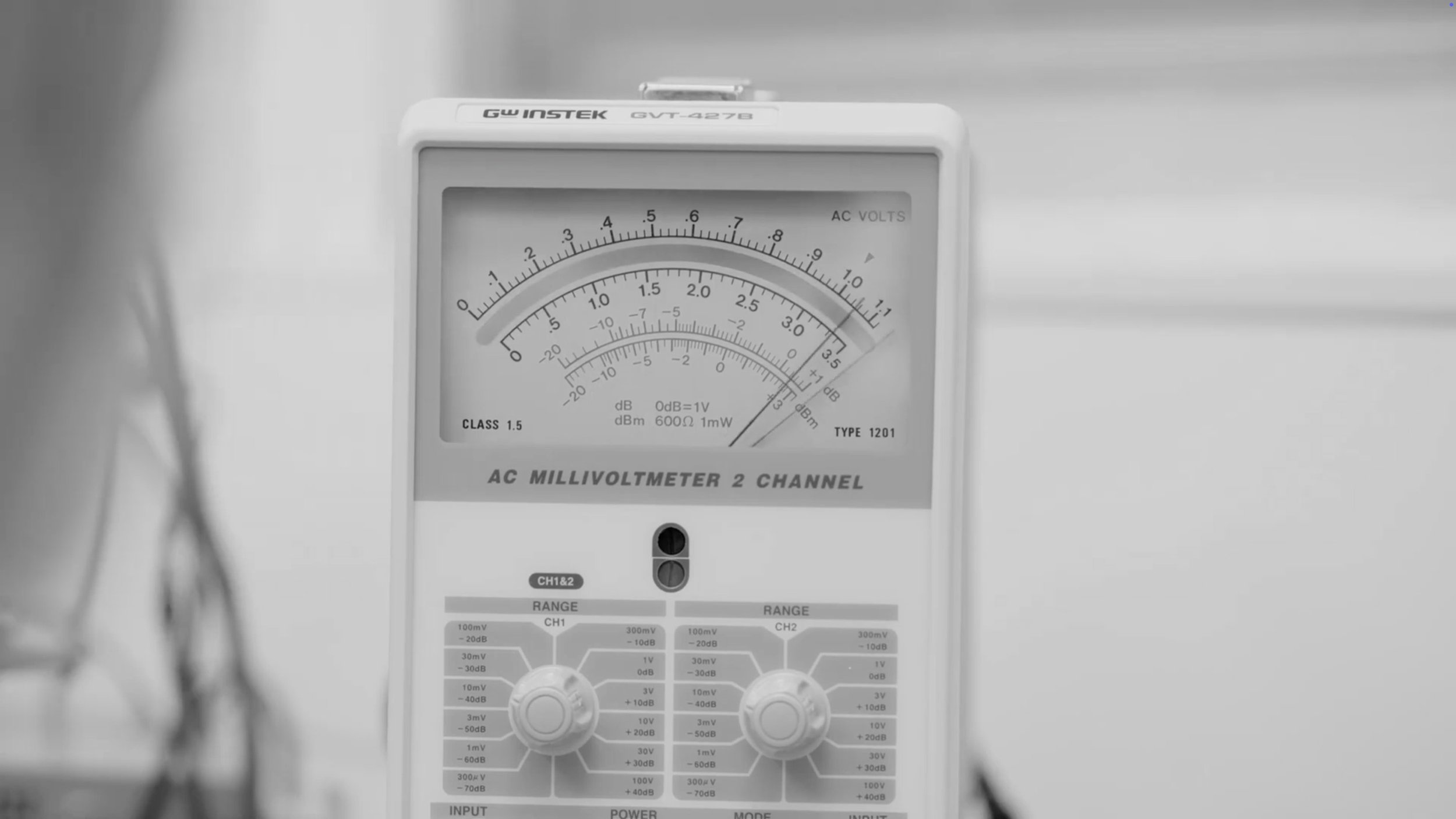

Once the cartridge is assembled, it undergoes rigorous testing and fine-tuning to ensure peak performance. Installed on a test jig, it is carefully measured for key attributes, including tracking accuracy, channel balance, channel separation, distortion elimination, and flat frequency response. Using test records in conjunction with precision instruments like an oscilloscope and a millivolt meter, the technician evaluates the cartridge's performance with exacting attention to detail.

If any discrepancies are identified, the technician makes fine adjustments to the suspension, ensuring that the cartridge meets the highest standards of fidelity. Once approved, the cartridge is meticulously mounted and secured within its model-specific body. Once completed, another technician inspects the cartridge one last time to ensure it meets the strictest HANA quality control. Finally, it is given its serial number and boxed for its lucky new owner.