BUILDING A HANA CARTRIDGE

Building HANA cartridges is a meticulous process combining traditional craftsmanship and advanced engineering. Every step, from coil winding to final packaging, is carried out precisely to ensure each cartridge delivers exceptional performance and musicality.

Follow the links below to learn more.

1: WINDING THE COIL

Ultra-fine 4N copper wire is meticulously wound onto the cross coil with precision, ensuring both mechanical and electrical balance for optimized signal generation and superior performance.

2: DAMPER AND SOLDERING

The damper is precisely installed in the wound coil to form an accurate magnetic circuit, then microscopically soldered for flawless signal transmission and electrical integrity.

3: Magnetic Circuit Assembly and Calibration

The magnetic generator is meticulously aligned with the cartridge frame for perfect tolerances. The front pole piece optimizes cantilever movement, while fine adjustments minimize distortion for natural sound reproduction.

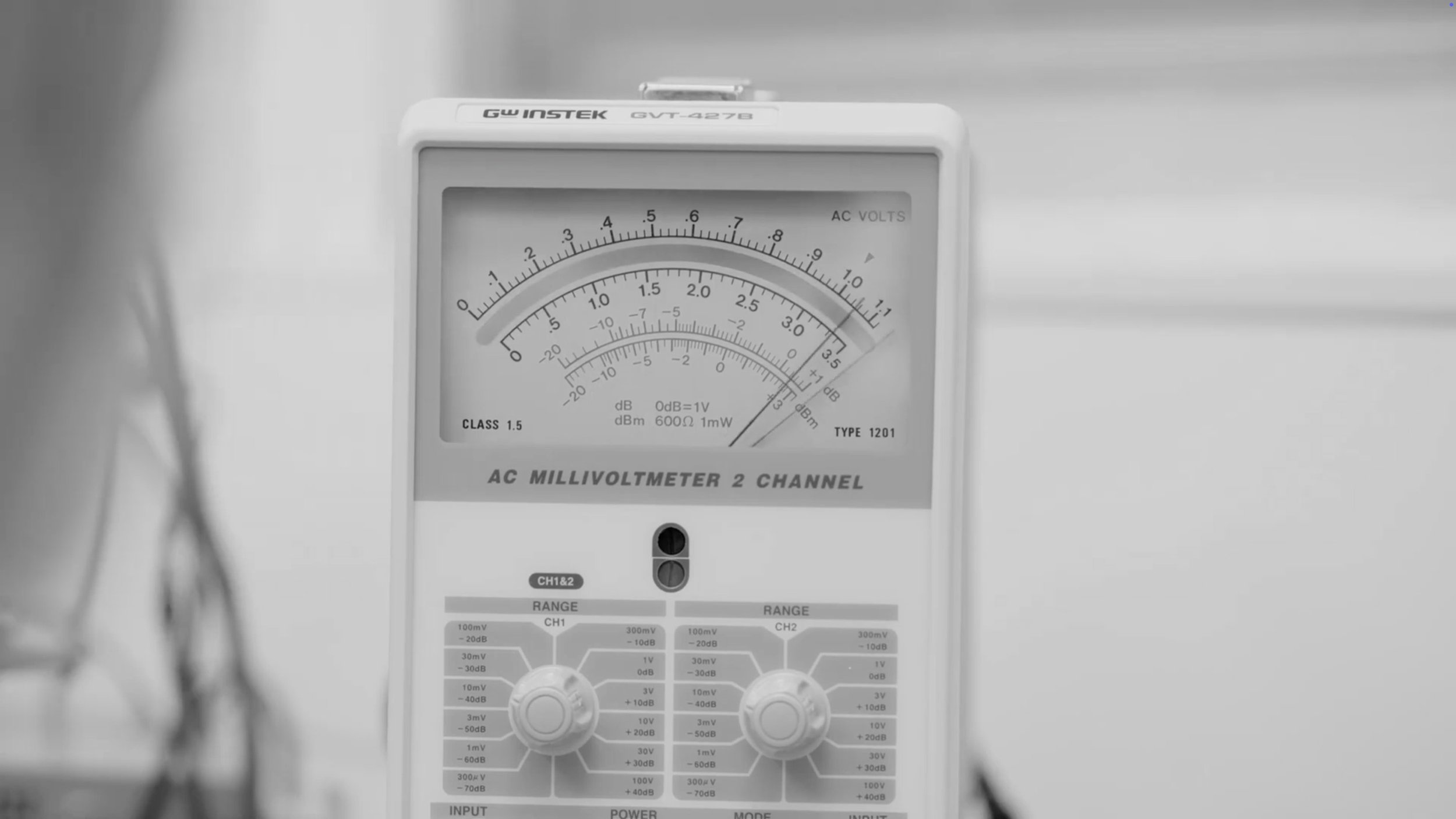

4: FINAL TESTING INSPECTION AND PACKAGING

Each cartridge undergoes rigorous testing for tracking, balance, and distortion-free performance. After fine suspension adjustments and final quality checks, it is securely packaged for delivery.